<< Station 3 | Back to industrial trail | Station 5 >>

The forest, the quarrying of mineral ore and the smelting of iron in Eastern Bavaria in prehistoric and primeval times

The dating of iron slag has revealed that iron smelting began in Eastern Bavaria in the late La Tène period (150 – 50 B.C.). The iron ore was smelted where it was quarried, as is proved by numerous sites in the Regensburg-Kelheim-Parsberg region.

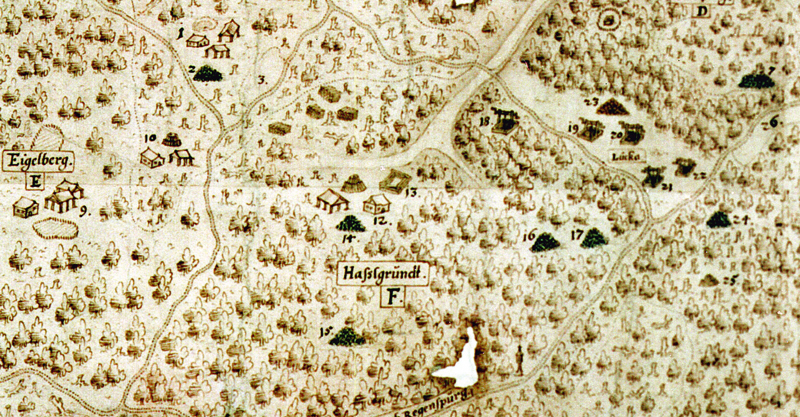

Illustration: Painten Forest near Kelheim, early 17th century. The map shows ore mines ( the ore was extracted by means of hand-winches), charcoal piles and smelting sites with slag heaps. The small pieces of ore were smelted on the spot. The so-called bloom produced in the smelting process (a lump of iron consisting of iron particles fused with other substances and with charcoal) was then taken to forges to be wrought.

Illustration: Painten Forest near Kelheim, early 17th century. The map shows ore mines ( the ore was extracted by means of hand-winches), charcoal piles and smelting sites with slag heaps. The small pieces of ore were smelted on the spot. The so-called bloom produced in the smelting process (a lump of iron consisting of iron particles fused with other substances and with charcoal) was then taken to forges to be wrought.

Illustration: Shaft in Frauenforst near Kelheim. The circular shaft with no wooden lining has a diameter of 80cm. The shafts were excavated as far as the stratum containing the ore, which was then extracted. They were fi lled up again, probably using spoil from neighbouring shafts.

Illustration: Funnel-shaped pit in Frauenforst near Kelheim. The earthen wall around the circular funnel is typical. Funnel-pits like this are also to be found in the Theuern and Wolfsbach area.

Illustration: Funnel-shaped pit in Frauenforst near Kelheim. The earthen wall around the circular funnel is typical. Funnel-pits like this are also to be found in the Theuern and Wolfsbach area.

After smelting had fi nished, the bloomery (i.e., the furnace) was broken open and the inhomogeneous lump of iron (bloom) was removed. The paste-like mass was then consolidated and forged. The slag component was beaten out under pressure and at a higher temperature and, after the remainder had been heated up again and carbon added, the product was malleable iron with a low carbon-content, which could then be wrought.