<< Station 4 | Back to industrial trail | Station 6 >>

The forest, its water, the quarrying and smelting of iron ore in the late meiaeval and early modern periods

Why the Upper Palatinate developed into one of the centres of European iron production in the late Middle Ages (from the 14th century)

In the 12th and 13th centuries, iron smelting was no longer carried out on the plateaus in the Franconian Jura where the ore was quarried. Instead smelters became a feature of the valleys, where the water power provided by rivers and streams allowed smelting to be done much more effectively in hammer mills. The stages in the process remained the same as in a bloomery. The furnace produced metallic iron, which coalesced with slag to form a mass (bloom). This slag was beaten out under the large power-hammer. When the iron was heated up in another furnace at a higher temperature, dissolved carbon penetrated its crystal lattice, thus creating an iron-carbon alloy – forgeable iron (steel).

Illustration: The mines needed considerable quantities of wood, as can be seen at St George‘s Pit in Sulzbach-Rosenberg. Only if the shafts and horizontal tunnels were firmly shored up, was it possible for mining to take place underground in the sometimes unstable host rock

Illustration (model in the East Bavarian Museum of Mining and Industry, Theuern):

Horse-driven whims, or winches, were common in the ore mines in Amberg. (Whims are mechanical devices which lift heavy items by harnessing the power of animals, which walk round in circles.) By this means the iron ore could be conveyed to the surface from the lower levels of the pits. Here, too, of course, the shafts had to be lined with wood.

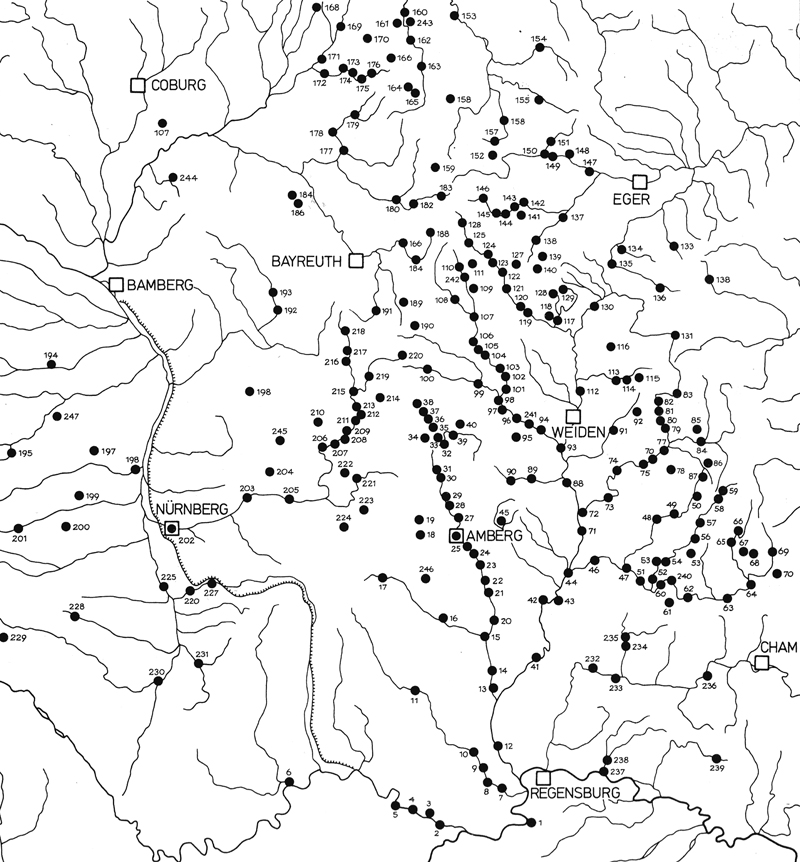

Illustration: Sites of hammer mills in the Upper Palatinate in 1475 (from: Ress, M. 1950) 247 mills are listed, including some in the Nuremberg region. In the Schnaittenbach area, two sites are marked, one of them in Holzhammer. The other site is probably that of the hammer mill in Kettnitzmühle.

Illustration: Sites of hammer mills in the Upper Palatinate in 1475 (from: Ress, M. 1950) 247 mills are listed, including some in the Nuremberg region. In the Schnaittenbach area, two sites are marked, one of them in Holzhammer. The other site is probably that of the hammer mill in Kettnitzmühle.

The organisational basis for the iron industry in the Upper Palatinate was the ‚Great Hammer Agreement‘, formulated in 1387. 69 individuals who owned smelting factories in Amberg, Sulzbach and Nuremberg, as well as other master smelters, joined together to form a cartel-like alliance. This contractual arrangement, allowing for certain changes, survived until 1648/49. One of the aims of the organisation was to deal with the crisis that resulted from the demand for huge quantities of wood for mining and for the production of charcoal for the mills. Limits were placed on the production of iron in order to halt the wholesale felling of trees. As there were close links between the mining of iron ore, its smelting in hammer mills and its distribution, the Upper Palatinate became a fl ourishing european centre of the iron industry. Iron production started to decline at the beginning of the Thirty Years‘ War. One reason for this was the fact that the Upper Palatinate still clung to the already old-fashioned technology of iron smelting in hammer mills. Only when the fi rst charcoal furnaces came into use (in Rosenberg, for instance, in 1693, and in Bodenwöhr in 1717) did the iron industry in the Upper Palatinate slowly start to recover. There was another boom in the second half of the 19th century as a result of the demand for railway tracks and of the introduction of more effi cient coke furnaces in Sulzbach-Rosenberg.

Illustrations: Holzhammer: hammer mill and settlement in about 1600 and Hammer mill at Kettnitzmühle in about 1600

Illustration: Hammer mill, grain mill and saw mill (from bottom to top) at Wolfsbach, Lower Vils Valley, (Amberg-Sulzbach District), early 18th century

Illustration: Hammer mill, grain mill and saw mill (from bottom to top) at Wolfsbach, Lower Vils Valley, (Amberg-Sulzbach District), early 18th century

Forestry and iron production

For several centuries, forestry and mining infl uenced the development of the woodland in this area. In particular, the iron industry was a vitally important factor from the 13th until the late 18th centuries, since it was dependent on charcoal.

Here are some fi gures that explain this: with 7 centner of charcoal 5 centner of iron could be produced from ore. To produce 7 centner of charcoal, however, 10 solid cubic metres of wood were required. Thus, a rough calculation shows that 2 solid cubic metres of wood were needed to produce 1 centner of iron.

The following statistics indicate the quantities of wood that were made into charcoal for iron production in the Amberg district (from: F. Fritsch 1974).

| Year | Iron Production (cwts) | solid cubic metres of wood |

| 1387 | 132600 | 265200 |

| 1475 | 231000 | 462000 |

| 1545 | 352000 | 704000 |

| 1609 | 415950 | 831900 |

There was, furthermore, an enormous demand for fi rewood, as well as for wood for mine shafts, etc., and for general building purposes.

To put it quite bluntly, it can be stated that twice as much wood was being used as could grow in the same period. Things could not go on like that, since the survival of the woodland was at stake; the capital represented by the woods was being exploited, not the interest they generated!

The condition of the forests deteriorated from decade to decade. In addition, there was a clearly noticeable reduction in the variety of tree species: pinetrees were most suitable for the production of top-quality soft charcoal, and this kind of tree was therefore most popular. The harvesting of wood for charcoal- production usually involved the complete felling and clearance of 50-60-year-old stands of young pines, the thickness of their trunks being most suitable for charcoal production.

Initially, reafforestation meant leaving the forest to re-seed itself naturally, but this was a slow process. In 1368, Peter Stromeier, a Nuremberg alderman, discovered how to regenerate overfelled woodland artifi cially by planting fir seed. In places where a couple of centuries earlier there had been speciesrich woodland containing pine, spruce, fir, beech, oak, lime, elm and birch, pine trees were now dominant. Whereas beeches reputedly made up a quarter of the woodland trees until as late as the 16th century, now there were only sparse stocks of pine trees.