<< Station 14 | Back to industrial trail | Station 2 >>

Hirschau

Schnaittenbach

The projekt

A geopark is a designated area containing a number of geotopes which are not only significant for the immediate area but which actually determine the nature of the surrounding landscape. It is vital to preserve such a site because geotopes, essentially, are key sources of information about the development of Planet Earth and its flora and fauna.

The Hirschau-Schnaittenbach Kaolin Mine GeoPark is located in Germany’s largest kaolin-mining district. Kaolin – also known as china clay – has been mined here since 1833, and the reserves of this raw material are expected to last for several decades yet. Nevertheless, besides continuing a long-term programme of landscape regeneration, the authorities have instituted a project to redevelop the huge open-cast pits by transforming them into a chain of artificial lakes.

The Hirschau-Schnaittenbach Kaolin Mine GeoPark differs from other geoparks in that the industrial landscape is still constantly changing here, allowing visitors to experience the dynamic process for themselves. The geopark will make it possible, even after mining activities have ceased, for visitors to grasp the importance of kaolin-mining for this region. Industrial Trail I pays special attention to the newly-created habitats for flora and fauna. Together with these factors, the long-term nature of the proposals for the Kaolin Mine GeoPark are what make it unique.

The Kaolin Mine GeoPark is part of a network that embraces Eastern Bavaria and Western Bohemia.

The Hirschau-Schnaittenbach Kaolin Mine GeoPark has three main features:

• The ‘Kaolineum’, a visitors’ centre at Monte Kaolino in Hirschau

• a working mine open to visitors in Schnaittenbach

• three industrial trails

Concrete

The information here is not presented on conventional boards but on elements made of concrete, a material that has also been produced almost entirely in the Hischau -Schnaittenbach mining district. The display boards at the first information point are made of a type of high-performance concrete that has recently been developed by Dorfner Bros, a company based in Hirschau.

Concrete is a building material that consists of water, cement and various additional materials. The cement bonds the components together. The material gets its strength from tiny crystal needles that assume crystalline form during the bonding process: they become firmly interlocked and fix the additional materials – e.g. sand and gravel – in the artificial stone matrix. Even standard concrete thus has enormous crush resistance – the equivalent of the weight of c. 250 small cars on a sheet of A4 paper.

The use of concrete with ever-increasing crush resistance is a basic tendency in the modern building industry. What is technologically unique about ultra-high-performance concrete is its extremely dense structure. If it has been produced under ideal conditions and has been subsequently treated in the correct way, it has hardly any pores or micro-cracks.

Thus, raw materials obtained from deposits in Hirschau-Schnaittenbach are used, together with water and cement, to produce a pioneering form of artificial stone – innovative building material for future generations!

How the kaolin deposits were formed

The kaolin deposits at Hirschau-Schnaittenbach are the most significant ones in Germany. They occur as a 60-meter deep bed in 220-million-year-old Mezozoic mean Buntsandstein. The minerals found here include quartz (70-80%), feldspar (8-12%) and kaolin (10-12%), in varying proportions.

The original formations consisted of weathered granite and gneiss from the nearby bedrock. The rubble that resulted from the weathering process was washed into the Hirschau-Schnaittenbach Valley. The consistency of the grains corresponds to the sedimentation in flowing water. The breaking down of the feldspar and the formation of clay-based minerals (the kaolinisation process) must have taken place immediately after the rubble was deposited.

In addition to these secondary kaolin deposits, there are also primary ones, e.g. in the Tirschenreuth area. In that district, the kaolin was formed in deeply weathered granite.

Mining began in Schnaittenbach as long ago as 1833.

(InfoPoint No. 6 on the Industrial Trail illustrates the mining and processing of kaolin.)

Kaolin (china clay)

Kaolin, also known as china clay, is a compound consisting of several clays deriving from kaolinite, dickite and nakrite. The chief component is kaolinite AI [OH8 I SiO4O10]

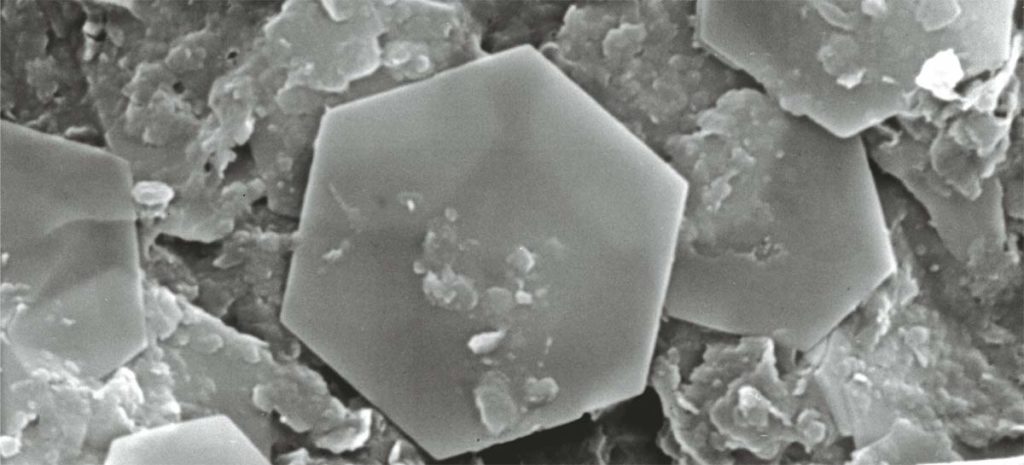

Kaolinite is a pure clay silicate containing water. In some cases it is definitely crystalline, in others it is extremely fine-grained and was originally in gelatinous form. The crystals are small, thin, pseudo-hexagonal discs.

The base minerals for the formation of kaolin are feldspars, which are present in granite and gneiss as rock-forming minerals, e.g.

potash feldspar K [AlSi3O8]

albite, or sodium feldspar Na [AlSi3O8]

Kaolinite develops as a result of chemical weathering when water is present. Silicates, including feldspars, have a complicated structure and they are split up into simple compounds as a result of absorbing hydrogen ions. The silicic acid then becomes a colloidal solution. During this process of decomposition, clay minerals of the kaolin type are formed in the acidic environment.

The iron ions that are present everywhere in this area and give the rock its brown tint also become a solution in this acidic environment and are washed out. This leads to the ‘bleaching’ of the rock.

Sechseckiger Kaolinitkristall, Rasterelektronenmikroskop-Aufnahme, ca. 4/1000 mm Größe

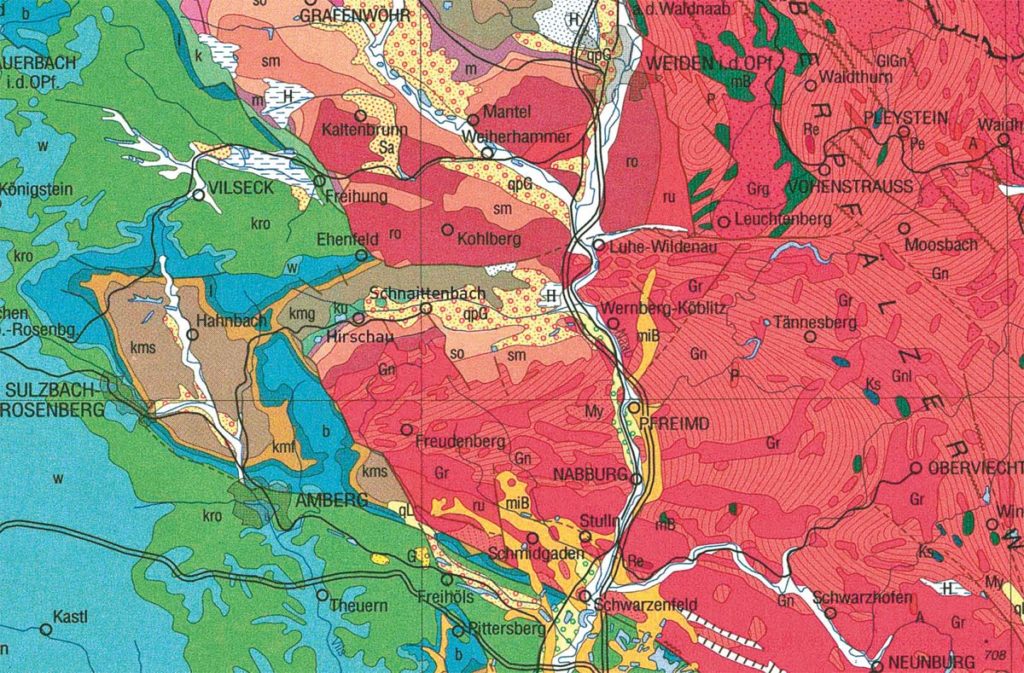

Geological map

The kaolin mine between „Bavarian Moldanubian“ and the Franconian Alb

Legende zur Geologischen Karte von Bayern 1 : 500 000, Ausschnitt: Mittlere Oberpfalz

Legende zur Geologischen Karte von Bayern 1 : 500 000, Ausschnitt: Mittlere Oberpfalz

Quelle: Bayerisches Geologisches Landesamt, 1997

| Periode | Beginn vor Mio. Jahren |

||

| H | Torf | Quartär | 2,6 |

| Sa | Flugsand | ||

| qpG | Terrassenschotter | ||

| miB | Braunkohlentertiär | Tertiär | 65 |

| kro | Oberkreide | Kreide | 140 |

| w | Malm | Jura | 200 |

| b | Dogger | ||

| kmf | Feuerletten | Trias | 250 |

| kms | Sandsteinkeuper | ||

| kmg | Gipskeuper | ||

| ku | unterer Keuper | ||

| mo | oberer Muschelkalk | ||

| mu | unterer Muschelkalk | ||

| sm | Buntsandstein Quarz – Feldspat – Kaolin Lagerstätte im Hirschau – Schnaittenbacher Revier |

||

| ru | Unterrotliegend | Perm | 300 |

| mB | Metabasit | Perm – Karbon | 350 |

| P | Quarzporphyr | ||

| Gr | Granit, ungegliedert | ||

| Grg | Granit, mittel bis grobkörnig | ||

| Gzf | Zweiglimmergranit | ||

| Gn | Gneis | Präkambrium | 550 |

| My | Perlgneis |

What the raw materials are used for

Quartz: quartz is used in the glass industry, the building industry and in many other fields.

Feldspar: this mineral is used in glass-making, for architectural ceramics, and in the porcelain industry – china consists of kaolin (50%), quartz (25%) and feldspar (25%) – as well as in the production of varnishes, enamel and electrodes.

Kaolin: about 60% of all the kaolin produced is used in paper-making. Kaolin is employed as a filler for giving paper body, and as a pigment for coating the surface of paper. Kaolin is also used for making porcelain (historically its main use), fibre-glass and in the production of building materials.

Beer mug with a pewter lid, (E.D. Dorfner & Co, Hirschau, 1898), Kaolin as a filler and as a coating pigment, an essential raw material in paper production